We are a business group involved in manufacture and supply of Gray Iron Castings & DuctileCastings for high quality engineering goods in General Engineering

| Box Size | 650 mm × 750 mm × 250 mm |

|---|---|

| Weight range of Casting | 10 Kg. to 70 Kg. |

| Annual Capacity | 4200 M.T. |

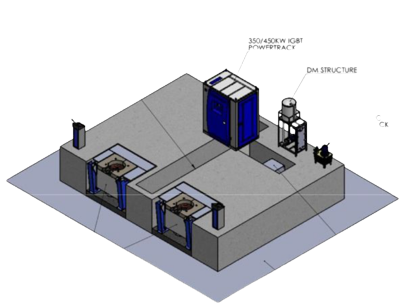

| Type Of Melting | Induction Melting Furnace (500 kg Capacity-2 No's) |

| Type Of Molding | Green Sand Molding (Semi Automatic |

| Type Of Cores | Cold Core Box |

| Material Grade | All Grades of Grey Iron & S.G. Iron (Ductile Iron) Castings as per IS, ASTM, ISO, DIN, EN, JIS, etc... Standards |

| Out Source Facilities | Pattern Making Heat Treatment Annealing Galvanizing Transportation |

We have installed a green sand plant with a capacity of 20 metric tons per hour sand recycling capacity.The sand plant is totally PLC controlled for the batch mixing and moisture addition, to control the quality and consistency of the sand mixed for molding. We have arrangement to supply sand from the sand plant to all the 5 molding lines that we have installed.We have a 100 tons hopper for the storage of return sand overhead which receives the return sieved and demagnetized sand after the Knockout phase. We have conveyor system to support the sand plant by distribution of sand throughout the plant according to the plant capacity. It consists of the underground conveyors for the collection of knockout sand and over head conveyors and bucket elevators to feed the sand back to the hoppers

We also make Cold Box core with 20kg capacity Cold

Box Machine (Multi shooting and Single shooting).

Core shooter cold box single station fully automatic

Core box machine : 2 no’s

All functions are managed by a P.L.C.

Ejection with horizontal.

Die platform size 600×600×400mm

Sand hopper volume 150 kgs